Repair & Rebuild Story

Repair of Dorman V12 saves client

£120,000 in replacement costs

Using our 23yrs of experience Octas Power succesfully repaired and reconditioned our clients 47yr old Dorman v12.

Location

Tyne & Wear

Generator Age

47yrs

Estimated £’s Saved

£120,000

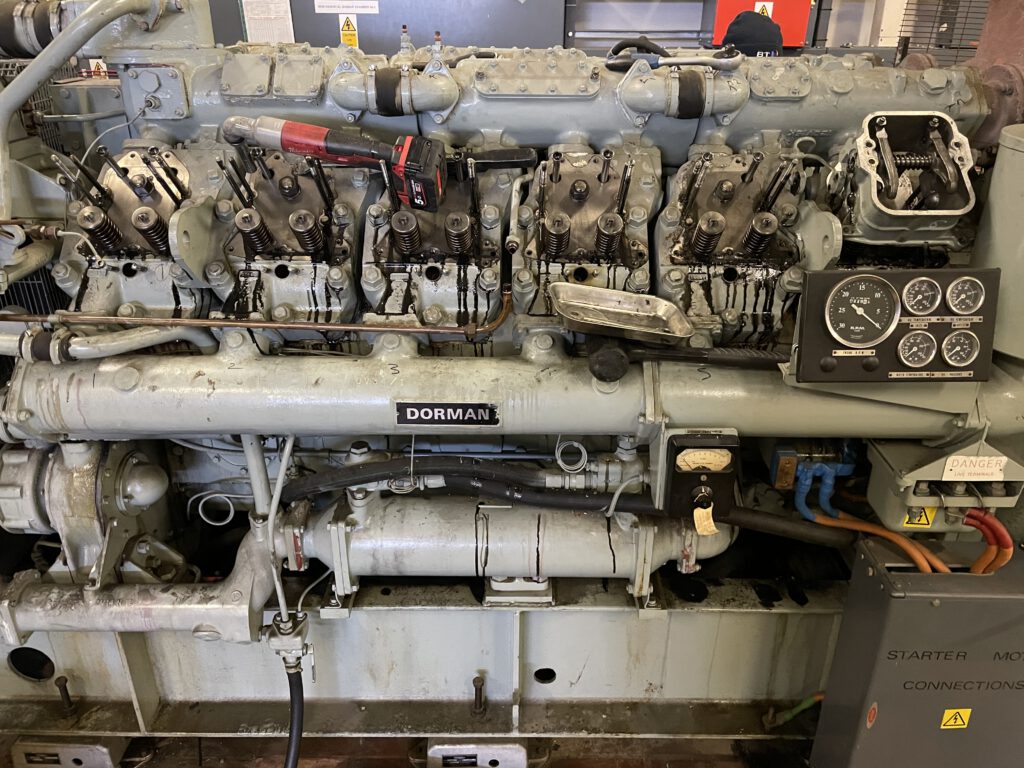

The Problem

The Dorman cylinder liner weep holes were leaking coolant which meant its liner seals had failed, However the cylinder head waterway seals had also been leaking for a number of years. Being a standby generator it only had 350 hours from new because of a city location with reliable mains electricity. The generator was originally installed in 1978 and the majority of its hours were from yearly load bank testing. Given it was barely even ran in it made perfect sense for the business to recondition the unit.

The Process

The Dorman was fully stripped down, watercooled exhausts, cylinder heads removed, pistons, cylinder liners, mechanical fuel pump and injectors. The generator was then fully rebuilt, all 12 cylinder liners were inspected and within tolerance unmarked. new liner o rings, piston rings, big end bearings and all cylinder heads were fully reconditioned. The fuel pump was overhauled along with injectors and new water jacket heaters. The set was fully load bank tested for 8 hours at customer request and finished in original paint. The overhaul saved the customer in the region of £120,000 in replacement costs.

The Results

More Case Studies

Repair & Rebuild

Dorman V12 Rebuild

Recondition

Lister HR2 Recondition

Rebuild